SEWAGE TREATMENT PACKAGES

Moving Bed Bio Reactor

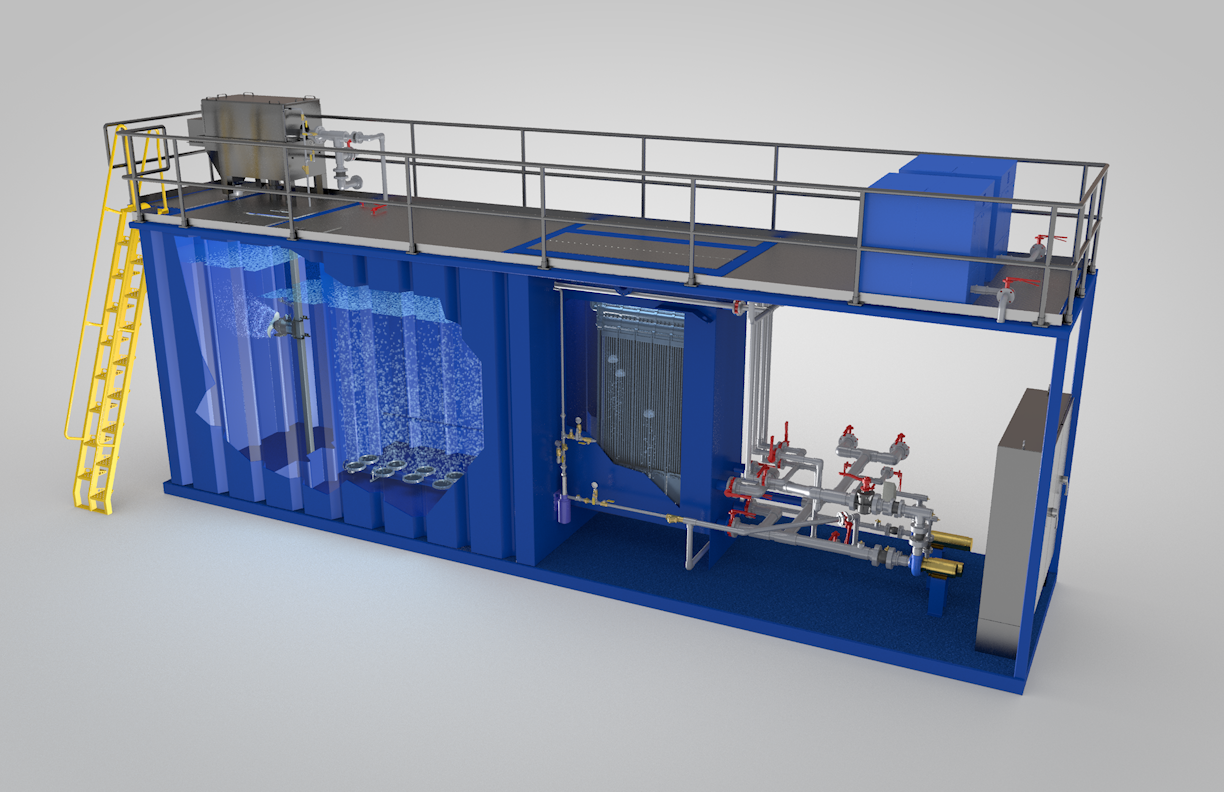

KGN Water’s offer MBBR water system to treat waste water from human waste. The MBBR system consists of an aeration tank (similar to an activated sludge tank) with special plastic carriers that provide a surface where a biofilm (bacteria) can grow. The carriers will be mixed in the tank by the aeration system and thus will have good contact between the substrate in the influent wastewater and the biomass on the carriers.

MBBR technology offer numerous benefits, such as robust biofilm, flexible reactor design, easy upgrade of existing plants, easy to operate and control, no sludge return needed in most applications, low load on particle separation stage

The technology utilizes the advantages of both activated sludge and other biofilm systems (e.g. biofilters, biorotors etc.) without being restrained by their disadvantages. The carriers are designed to provide a large protected surface area for the biofilm to grow and optimal conditions for the bacteria culture when the carriers are suspended in water.

Membrane Bioreactor

Membrane Bioreactor (MBR) is a process that combines a membrane ultra / micro filtration process and activated sludge process. (The MBR process is used in place of the secondary sedimentation tank and sand filter used for tertiary treatment in the conventional activated sludge process.) KGN Membrane Sewage Treatment Plant provides features such as space saving, easy operation and high-quality treated water which is reusable. In addition, advanced treatment of nitrogen and phosphorus removal can be achieved by anoxic / aerobic treatment.

Sequencing Batch Reactor

Sequencing Batch Reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter (measured as biochemical oxygen demand (BOD) and chemical oxygen demand (COD)). The treated effluent may be suitable for discharge to surface waters or possibly for use on land.

Drop us a line

Contact Us

PRODUCTS & SERVICES

HEAD OFFICE (UAE)

KGN MEASURING & CONTROL SYSTEM LLC

Office #708; Al Qusais Plaza

Damascus Street

Dubai, UAE

Tel: +971- 42659689

info@kgnglobal.com

Web: www.kgnglobal.com

FACTORY

KGN GLOBAL PRODUCTS & SERVICES FZC

ware House No: 1J 04-3 & 3A

PO Box: 42502

Hamriyah Free Zone, Phase 1

Sharjah, UAE

Tel: +971-67475025

Web: www.kgnglobal.com

BRANCH OFFICE

KGN OIL AND GAS EQUIPMENT LLC

Office No 51

Ascent Business Centre

Musaffah, Abu Dhabi, UAE

Tel: +971-24432249

Web: www.kgnoilandgas.com